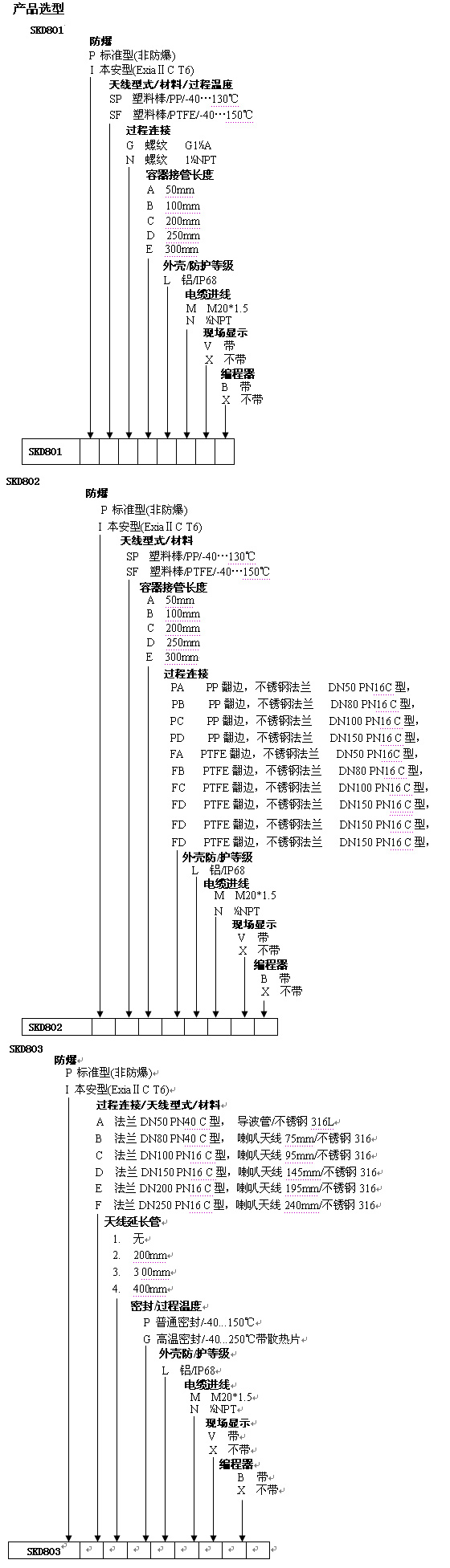

Measurement principle

Low emission energy very short microwave pulse transmitter and receiver through the antenna system. Radar speed of light running. Running time can be converted to the electronic components of level signals. Time extension of a special way to ensure stability in a very short time and accurate measurement. Even if the situation is more complex conditions, the existence of a false echo, with the latest micro-processing technology, and debugging software can accurately analyze the echo of level。

Input

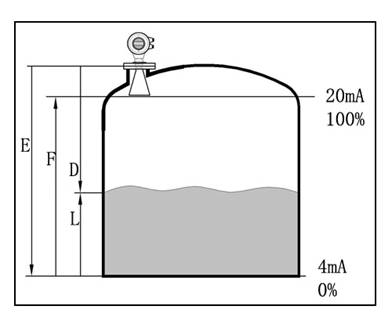

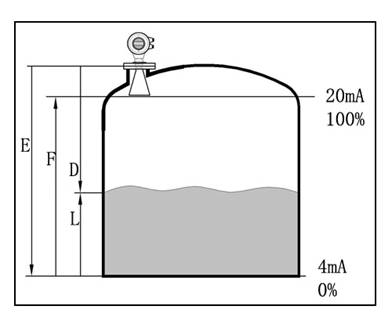

Antenna to receive the reflected microwave pulses and transmits to the electronic circuit, a microprocessor which signals are processed to identify the micro-pulse echoes generated by the material surface. Correct echo signal recognition by the intelligent software to complete, up to millimeter accuracy. The distance D from the material surface and the pulse is proportional to the time schedule T;

:

D=C×T/2

Where C is the speed of light

Because of the known empty distance E, the material level L,:

L=E-D

Output

By entering the empty height of E (= zero), full tank height F (= Full Scale), and some applications to set the parameters, application parameters will automatically adapt to the instrument measurement environment. Corresponds to the 4-20mA output。

Application of media:

JGD800 series of radar level instrument for liquid, paste and pellets of level non-contact continuous measurement for temperature, pressure variation in; the presence of inert gases and volatile situations。

Microwave pulse measurement methods, and frequency bands in the range of industrial work. Lower energy beam, can be installed on a variety of metals, non-metallic container or pipe, no harm to humans and the environment。

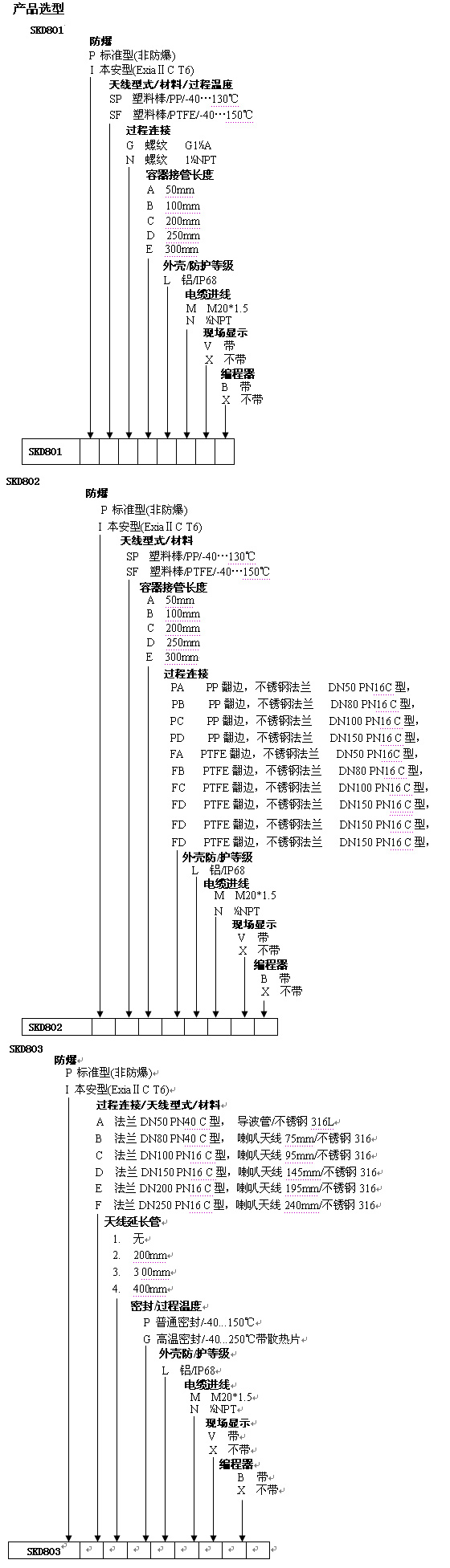

产品简介:

JGD800Series of smart radar level meter |

|

|

|

Category |

JGD801 |

JGD802 |

JGD803 |

Should be used |

Simple process conditions, corrosive liquid, slurry, solid

For example:

liquid water storage tank

acid tank

Slurry tank

Solid particles

Small storage tanks |

Storage or process vessels corrosive liquid, slurry, solid

For example:

liquid water storage tank

acid tank

Slurry tank

Solid particles

Small storage tanks |

To adapt to a variety of storage containers or process measurement environment, liquid, slurry, solid

For example:

Crude oil, light oil storage tank

Coal, pulverized coal position

Volatile liquid storage tank

Coke material level

Slurry tank

Solid particles |

Measurement range |

20 m |

20m |

35m |

Process connection |

Thread |

Flange |

Flange |

过 程 温 度 |

-40-130℃ |

-40-150℃ |

-40-250℃ |

Process pressure |

-1.0-3bar |

-1.0-20bar |

-1.0-40bar |

Repeatability |

± 3mm |

± 3mm |

± 3mm |

Accuracy |

< 0.1% |

< 0.1% |

< 0.1% |

Frequency range |

6.8GHz |

6.8GHz |

6.8GHz |

Ex / protection |

EXiaIICT6/IP68 |

EXiaIICT6/IP68 |

EXiaIICT6/IP68 |

Signal output |

4…20mA/HART(Two lines) |

4…20mA/HARTTwo lines) |

4…20mA/HART(Two lines) |

Installation Guide

Installation Guide

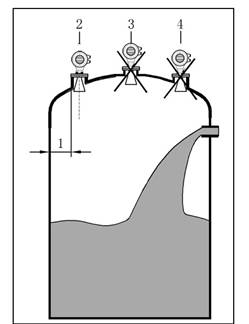

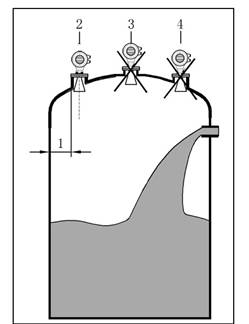

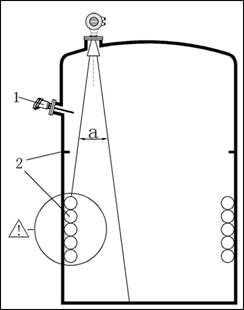

- Recommended distance (1) short tube wall to wall installation:

- Tank diameter from the tank wall is 1 / 6, the minimum distance of 200mm。

- Can not be installed above the feed inlet (4)。

- Can not be installed in the center position (3), if installed in the center, will produce multiple false echo, echo interference can cause signal loss。

- If you can not maintain the instrument and the distance between the tank wall, the wall can cause false echoes media will adhere, when debugging the instrument should be a false echo storage。

|

|

|

|

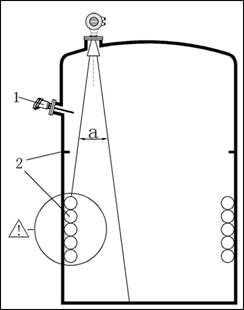

Tank installation

- The signal beam, the installation should avoid the following things (1): for example limit switches, temperature sensors。

- Symmetric device (2), such as vacuum rings, heating coils, baffles, etc。

- If the tank (1) (2) interfere with the object should be used to measure waveguide。

The best installation options

- Antenna size: the larger the antenna, the smaller the beam angle, interference echoes will be weaker。

- Antenna adjustment: adjust the antenna to the best measurement position。

- Waveguides: waveguide to avoid interference echo。

|

|

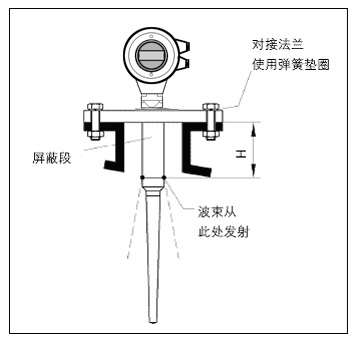

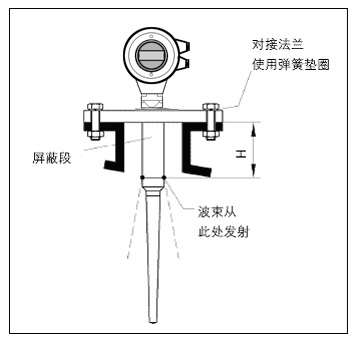

Tank installation(JGD801、JGD802)

Standard installation

- Radar antenna is not tilted to the tank wall。

- In order to minimize the temperature in the butt flange connection must use the spring washers。

- Rod antenna must extend to install short pipe。

- Vertically rod antenna, do not let the radar beam pointing tank wall。

|

|

|

|

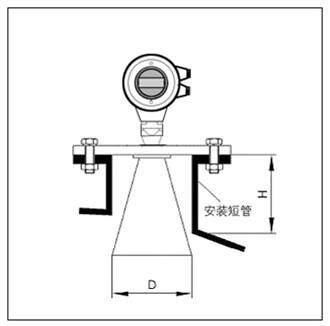

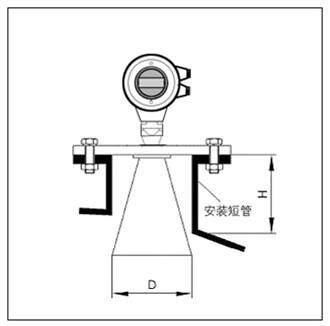

Tank installation(JGD803)

Standard installation

- Radar antenna is not tilted to the tank wall。

- Horn antenna must be extended a short pipe installed, otherwise use the antenna extension pipe。

- Horn antenna must be adjusted to the vertical, do not let the radar beam pointing to the tank wall。

|

|

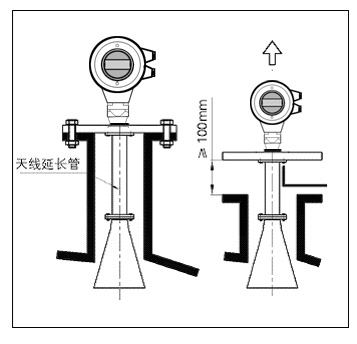

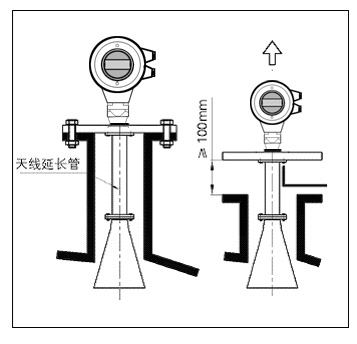

Short pipe installed using a longer antenna extension tube

- When the horn length is less than installing a short length of pipe should be used when the antenna extension pipe。

- If the horn diameter is greater than the diameter short pipe installed, including the extension of the antenna, including the need to pipe installed inside the container, and meter elevation. Select extension pipe to raise the instrument at least 100mm。

|

|

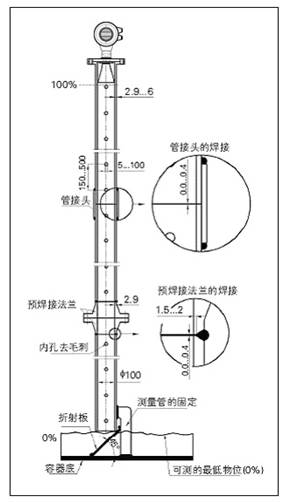

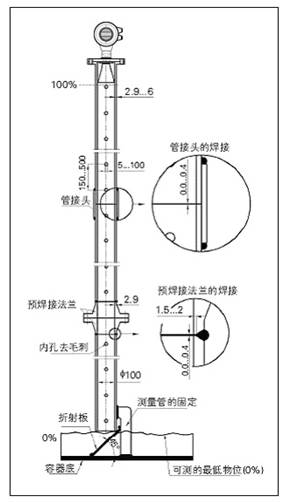

Installation of waveguide

- Guided wave radar sensor tube or pass through the tube measurement, the measuring tube to play the role of guided waves. Here is a measuring tube (waveguide structural map)

- Measuring tube wall must be smooth, if possible, measure the tube diameter needs to match the diameter of the bell, use the vertical extension welded stainless steel tube. You can pre-welded or welded flange extension measuring tube。

Must be noted:

- Welding, can not produce bumps or flanges. Alignment of the flange and the measuring tube fixed, and then welded. Welding not penetrates the measuring tube wall, tube wall must remain smooth, we must carefully remove the seam and not smooth place, otherwise it will create a strong false echoes。

|

|

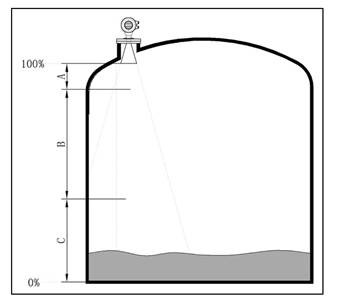

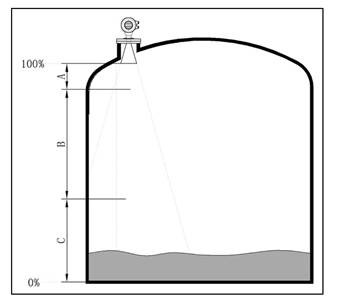

Measurement conditions

Note

- Measuring range from low beam can reach the point began to calculate, but in exceptional circumstances, if the tank as low as concave or tapered, when the material level is below this point can not be measured。

- If the media when it is in a low dielectric constant low level, the tank low visibility, this time in order to ensure accuracy, it is recommended to be set at zero position of the low height of C。

- Measurement of cutting-edge theory to the location of the antenna is possible, but considering the impact of corrosion and adhesion, the final value of measuring range should be from the tip of the antenna at least 100mm。

- For overflow protection, define a safe distance attached to the blind spot on。

- Minimum measuring range and antenna-related。

- With different concentrations of both foam can absorb microwaves, and can be reflected, but in certain conditions can be measured。

Action beyond the measuring range

When the measuring range exceeded, the instrument output is 22mA current。

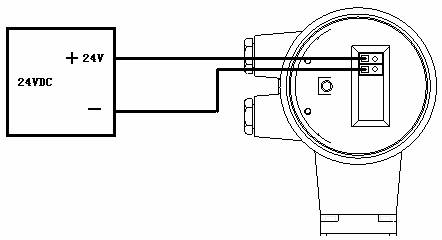

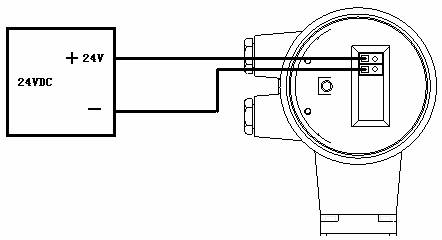

Wiring

Debugging

JGD800 three ways you can debug:

- Through the display adjustment module JGPM

- By commissioning software JGSOFT

- By HART handheld programmer

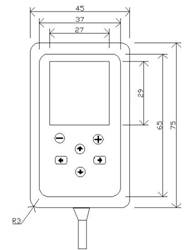

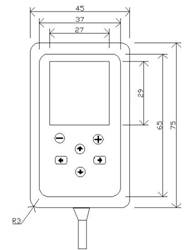

Live programming module(JGPM)

- JGPM programmer by the six buttons and an LCD screen that can display menus and adjust the parameters. Its function is equivalent to an analytical processing instruments。

|

JGPM

|

|

|

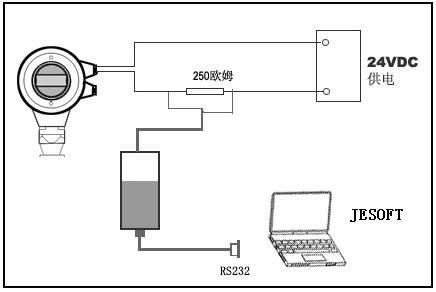

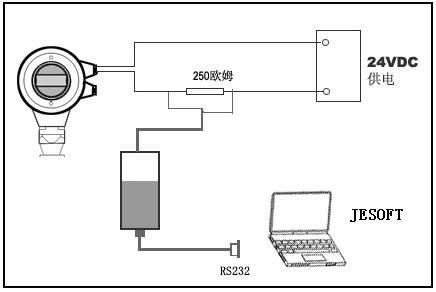

AdoptionJGSOFTSoftware debugging

No matter the kind of signal output, 4 ... 20mA/HART, radar sensors are available through software debugging. Instruments used BTSOFT software debugging, you need a meter CONNECTCAT drive。

Use of software debugging, to the radar instrument power 24VDC, while front-end connected HART adapter plus a 250 ohm resistor. If the integrated HART resistance (internal resistance of 250 ohms) power meter, you do not need additional external resistor, HART and 4 ... 20mA adapter cable parallel。

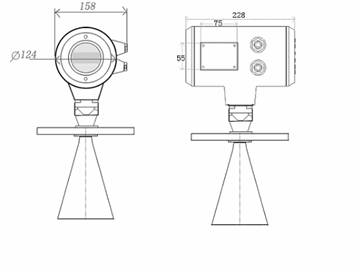

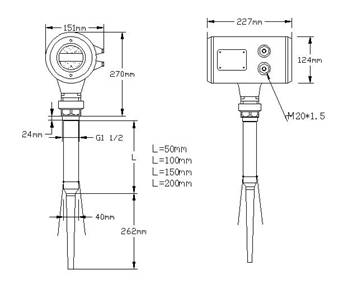

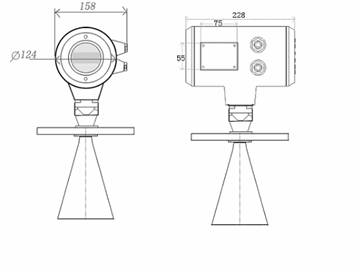

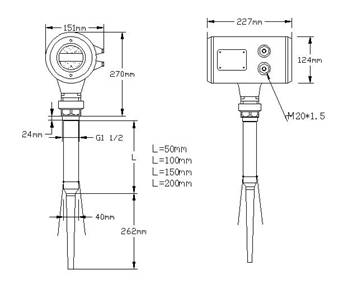

JGD800Family size

ProgrammerSize

Technical data:

Basic parameters

Frequency:6.8GHz

Wave beam angle: 24°JGD801, JGD802

18°JGD803 WithDN150 flange

14°JGD803 WithDN200 flange

12°JGD803 WithDN250 flange

Measuring range:0…35m

Repeatability :±3mm

Resolution :1mm

Sample: echo sample 55/s

Response speed:> 0.2s (depending on usage)

Current signal:4…20mA

Accuracy :<0.1%

Antenna material JGD801、JGD802为PP/PTFE

JGD803 for the 316L stainless steel

HART protocol communication interface

Process connection JGD801 (PP, PTFE antenna): G1-1 / 2 316L stainless steel,:

JGD802 (rod antenna): flange flange DN50,DN80,DN100,DN150

JGD803(Horn antennas are):法兰DN50,DN80,DN100,DN150,DN200,DN250

Power supply:24V DC(+/-10%),Ripple voltage:1Vpp

Power consumption:max22.5mA

Environmental conditions temperature:-40℃…+80℃

Vessel pressure (gauge pressure)-1…40bar

Explosion-proof certification ExiaII C T6

Shell of protection IP68

Two-wire connection sharing a power supply and signal output of two conductors

Cable entry: 2 M20 × 1.5 (cable diameter 5 ... 9mm)

|