The immersion electrical heater is chiefly applied in the direct contact mode of fluid heating.It features fast heat exchange and high thermal efficiency.It has the varieties of water heater,oil heater and gas heater.Its heating element power density,I.e. the power per unit of heating area of the heating element,is an important parameter of the electrical heating element,which has a direct bearing on the performance and working life.The working out of the value is a highly specialized problem,being under the influence of many factors (media flow rate,tempt,physical and chemical properties and direction in which the medium flows past the element etc).

Taking a too-high value will mean overheating and sintering and in serious cases causes damage to the heating element.While taking a too-low value will mean a large volume and a drastic rise of cost.Depending on the different applications electrical heaters adopt different power density.One common thing in terms of structure is that one tubing plate carries a number of heating tubes,at the ends of which is a supporting plate or supporting tube to make all heating tubes an integral whole.That way vibration of single heating tube caused by medium flowing is reduced.In the terminal box the overheating control is fitted as a protection device of the electrical heating elements.

?

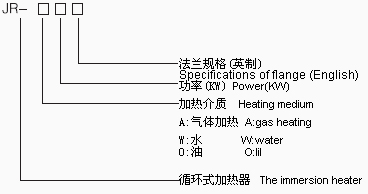

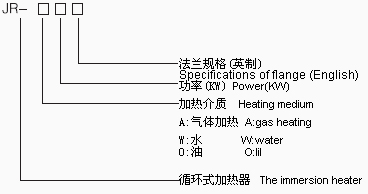

The Type signifies:

Notes:

- Heater may be made of carbon steel or stainless steel.Heating temperature is to be below 100℃.If heating is to be in the range between 100℃-200℃ a heat diffusion sector of 100 should be added bwtween the flange and terminal box,whose dimensions is A+100.If heating temperature needs to be even higher the heat diffusion sector shall be made longer.For specifics please contact our tech dept.

- Adopt the threaded connection.

|